Unlocking the Secrets of Low-Volume Manufacturing Services: A Professional Guide

Unlocking the Secrets of Low-Volume Manufacturing Services: A Professional Guide

Low-Volume Manufacturing: What is it?

A specialist service known as low-volume manufacturing service provides parts of complete production quality in quantities that vary from one item to a few thousand. It’s perfect for taking an idea from concept to prototype and serving as a transitional step before going into full-scale production. Low-volume manufacturing is regarded as a specialty service since most manufacturers are unwilling to engage in it. Their supply chains and assembly lines are set up to take advantage of economies of scale when producing in huge quantities.

Since that strategy is the most effective in guaranteeing the lowest costs per item, there can be nothing wrong with it. Nevertheless, it typically necessitates a commitment to pricey tooling and high minimum order volumes. However, what should a product developer do if they wish to begin with minimal product volumes, ranging from one component to a thousand? Here is where Star Rapid comes into play.

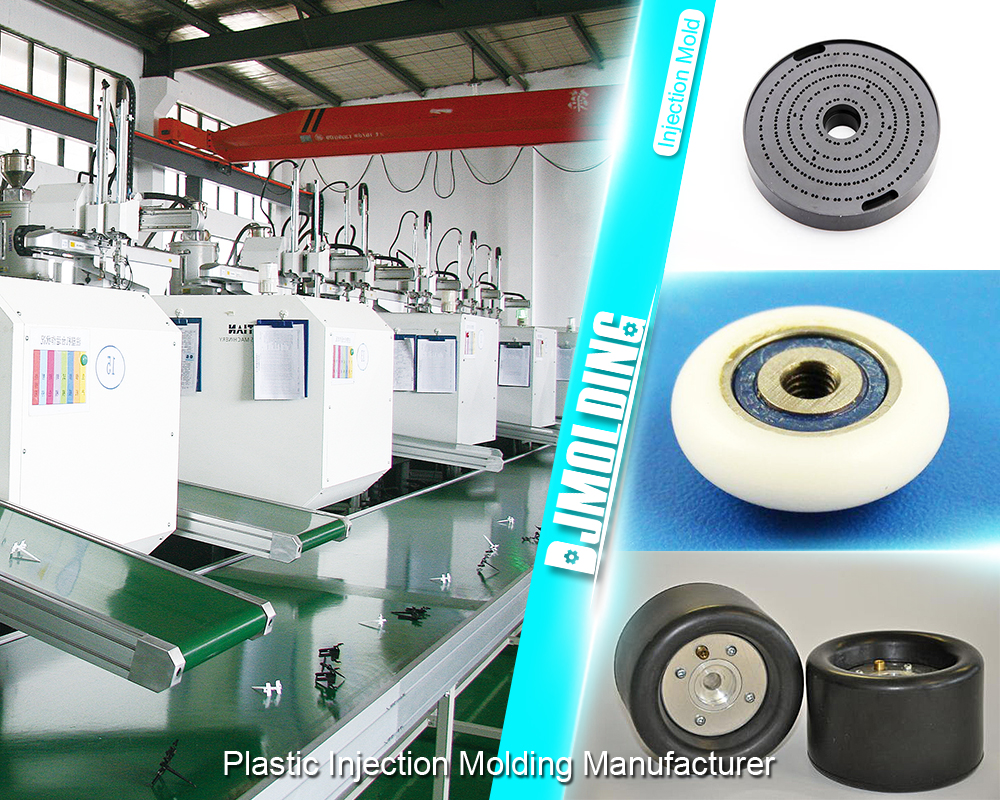

Injection molding is one example of a mass production technique where tooling may easily exceed $10,000 or more, and it can delay production schedules by weeks or months. Because the cost per item drops when the costs are split over thousands of parts, manufacturers can use mass manufacturing to offset these high upfront capital prices with high-volume orders. The mass manufacturing processes created to produce similar parts in large quantities limit the economic viability of making customized or highly customized products.

On the other hand, high-mix low-volume (HMLV) production, sometimes referred to as custom manufacturing, is the manual manufacture of products based on customized requirements, and it is typically carried out in small workshops. This leads to a higher price per component for custom items because of a significant amount of human labor and decreased productivity. For similar reasons, scale customization, the process of producing huge quantities of uniquely customized goods, has never proven to be financially feasible.

Low-Volume Manufacturing Situations

Manufacturers are under constant pressure to innovate, enhance quality, and reduce costs in order to maintain their competitiveness and optimize profits. Let’s examine several low-volume manufacturing service, from minimizing supply chain bottlenecks to crossing the gap between prototype and mass production.

Personalization

Customers today are investing greater amounts of time and money in finding goods that meet their unique demands and specifications. To keep up with demand, more options for tailored, personalized goods and experiences are required. Small-scale manufacturing can assist businesses in scaling customized goods for mass-market prospects without requiring them to make expensive tooling investments. Companies should reconsider how goods are produced and investigate fresh business strategies, such as mass customization, that enable them to better meet the wants of each unique client.

Product Development

Designers may create unique goods that are challenging to construct using conventional methods by pushing the limits of design complexity, optimizing structures, and customizing parts at no additional expense thanks to cutting-edge tools like 3D printing. With the use of 3D printers, you can make intricate parts and structures with characteristics like extensions, microchannels, and organic shapes that would be expensive or perhaps impractical to make with conventional manufacturing techniques. This opens up new design and engineering options by enabling the consolidation of multi-part assemblies, which reduces weight, strengthens weak links, and shortens assembly times.

Manufacturing of bridges

A step in the item’s development process called “bridge manufacturing” connects prototype and production. Low-volume production can be used by companies in any industry to swiftly and cheaply manufacture smaller batches of products before moving on to scale production. Before investing in expensive tooling for mass production, they can lower the risks associated with mass production by adopting pilot operations for evaluation of goods, pre-sales, or market validation.

Technologies for Manufacturing Low-Volume Products

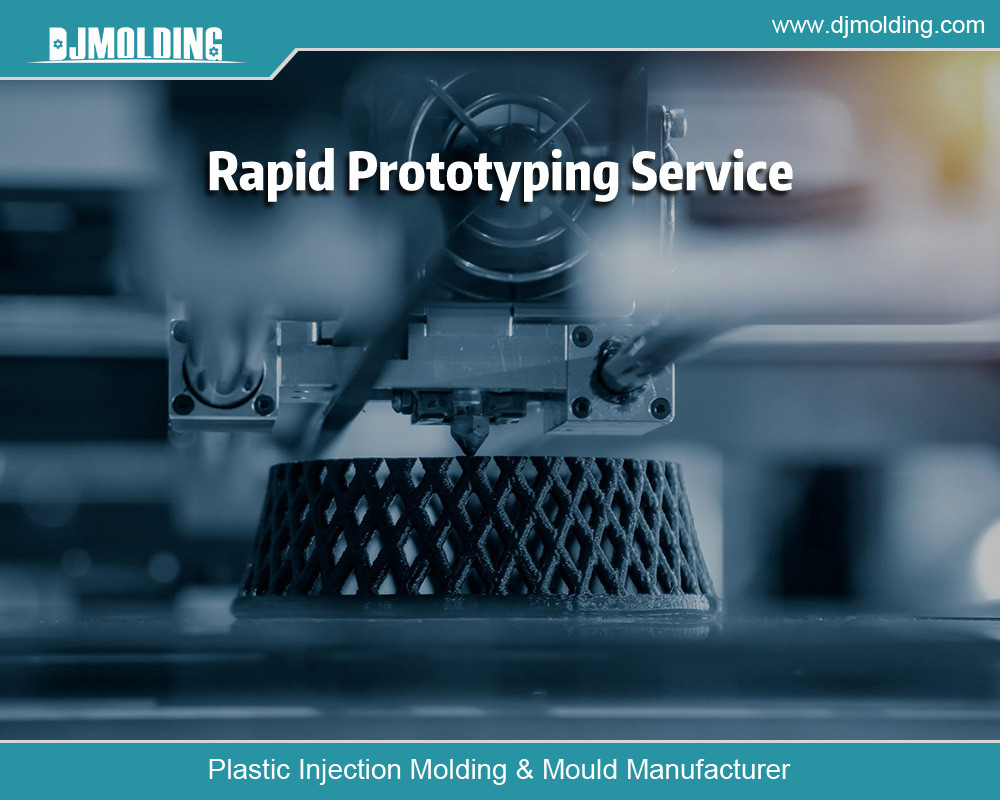

3D printing service

For many years, three-dimensional printing has been widely used in product development and prototyping. This developing technology is now being used extensively in manufacturing. Manufacturers are already using 3D printing’s adaptability in the development of their goods to create fast tooling like injection molds or the process of thermoforming molds, as well as internal tools like puzzles, components, and other manufactured aids.

Production Procedure

Design: Use a CAD program to design your model or start from a 3D scan of an already-existing model, an MRI, or an intrascan.

Print setup: Models are aligned and set out within a printer’s build volume, support structures are added (if necessary), and the supported model is sliced into layers using print preparation software.

Printing: Using a 3D printer, pick the correct materials and technology, then 3D print the part.

After processing: After printing is finished, the components are taken out of the printer, dried, cleaned, or post-cured, depending on the technology, and any necessary support structures are removed. The parts can be further post-processed using additional finishing procedures, decorated, or coated.

CNC Equipment

The manufacturing techniques that use CNC (computer numerical control) instruments are subtractive. They begin with solid metallic, plastic, or other material blocks of data, bars, or rods that have been sculpted by the removal of material using drilling, grinding, cutting, and boring techniques. CNC tools are more difficult to set up and use than additive manufacturing tools, and certain materials and designs may need unique processing, handling, placement, and tooling.

Because of this, they are more expensive for one-off pieces than additive methods and are more appropriate for smaller batch sizes. For limited-volume production applications like pulling devices, gears, and bushings that have difficult-to-mold designs and strict tolerances, machining is perfect. CNC machining can create high-quality components from a variety of materials swiftly and with minimal to medium setup expenses.

Compared to 3D printing, machining tasks are more constrained by part geometry. The cost per part of machining rises as part complexity increases. Costs are raised by cuttings, pass-throughs, and embellishments on numerous part faces. Certain geometries, like curving interior pathways, are not easy or feasible to create with traditional subtractive procedures, and in machining processes, consumers demand allowances over tooling access to them.

Quick Tooling

The term “rapid tooling” refers to a variety of methods for easily and effectively creating equipment in conventional manufacturing processes like thermoforming, injection molding, or casting in order to produce parts in smaller quantities or on short notice. The most frequent material used to make conventional tooling is durable metal, which is achieved through processes like metal casting and machining. These procedures are more appropriate for large-scale manufacturing cycles, but they are also costly. Manufacturing cycles are lengthened, and costs increase when tooling rounds or tooling intended for small-batch manufacturing are produced.

For more about the unlocking the secrets of low-volume manufacturing services,you can pay a visit to Djmolding at https://www.djmolding.com/low-volume-manufacturing-service/ for more info.