Custom injection molding services are the solution to many design problems

Custom injection molding services are the solution to many design problems

In the past many manufacturers had to face several design drawbacks because there was no industry that could make their ideas come true.

Previously many manufacturers had to face problems in each of the stages of manufacturing their products, finding the most practical solutions for each, but at a rather high cost, since many of these represented a significant increase in production costs, and in many cases they also involved a design modification that became increasingly evident to the manufacturer and its customers.

It was not until long after the plastic injection method was developed that a mold was created that could vary.

Although the plastic injection manufacturing method has existed for almost two millennia, the molds used to be fixed structures that could not be changed, this led the manufacturers to limit their creative process very much and the designs were limited to a large extent.

Many of the manufacturers began to develop methods to change the reality of fixed molds, not only because this represented a huge limitation for their customers, but also because when a client presented a design proposal that included a mold that was not available, they had to invest some extra resources to get another mold and manufacture the order completely.

After several attempts it was possible to design a changing system for all the molds owned by the companies dedicated to the manufacture of products through the plastic injection molding method.

After the design of the first variant mold, many improvements were implemented.

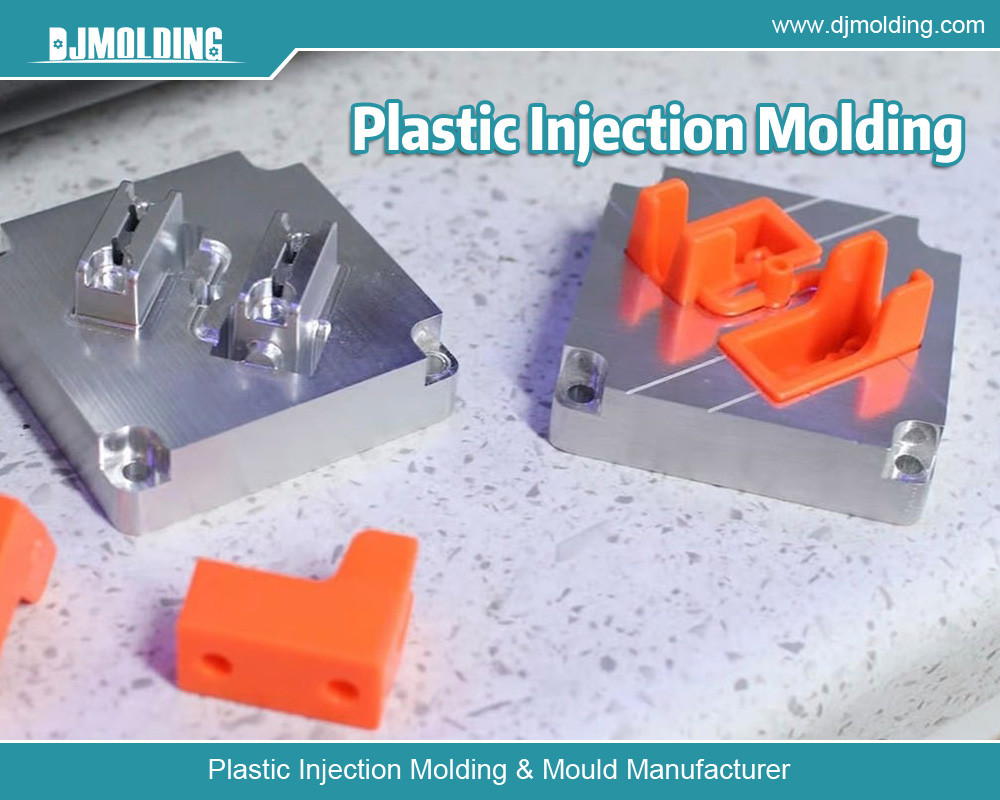

The mold created and implemented by various industries is able to vary in shape, size and thickness, this solution led to all manufacturing industries offering their custom injection molding services and many others requesting these services, since it was the best option for the cementation of all the necessary parts to assemble all its products.

Having a mold of this type allowed manufacturers to have the opportunity to offer custom injection molding services to all their customers, and these in turn were able to exploit their maximum design potential, creating the most appropriate and complex variations, without having to worry if it was possible or not to manufacture them, since it was evident that the machines had been created to achieve the most complex figures that could be proposed.

Another of the benefits offered by the variation of the mold was the variation of the colors of the material at various levels, this especially when it comes to 3D prints, since these are generated more precisely, layer by layer, in this way You can optimize the customization of all the parts involved in the production.

Due to the ease with which these molds can change, it is very easy to comply with the manufacturing speed and the quantity of pieces that are generated during a certain time. All these improvements led to each plastic parts manufacturer adopting new work methodologies, exponentially improving the lives of all its customers and increasing in large numbers the amount of production and saving a lot of money in costs.

For more about custom injection molding services are the solution to many design problems, you can pay a visit to Djmolding at https://www.djmolding.com/custom-plastic-injection-molding/ for more info.